Home » Solutions for industry » Recycling and Circular Economy

Taking advantage of the resources contained in waste is a requirement of society and the industrial sector, as we are currently facing a shortage of materials, rising prices and complexity in the environments where most raw materials are found.

For this purpose, it has been decided to make the circular economy and “0” landfill a priority. The sector requires advanced material separation technologies to give the right qualities to fractions derived from waste streams, new methods for chemical recycling of plastic waste to obtain monomers and chemical products, as well as ensuring traceability. Different waste treatment solutions, processes and technologies must coexist in order to adapt to each waste stream, industrial environment and local circumstances.

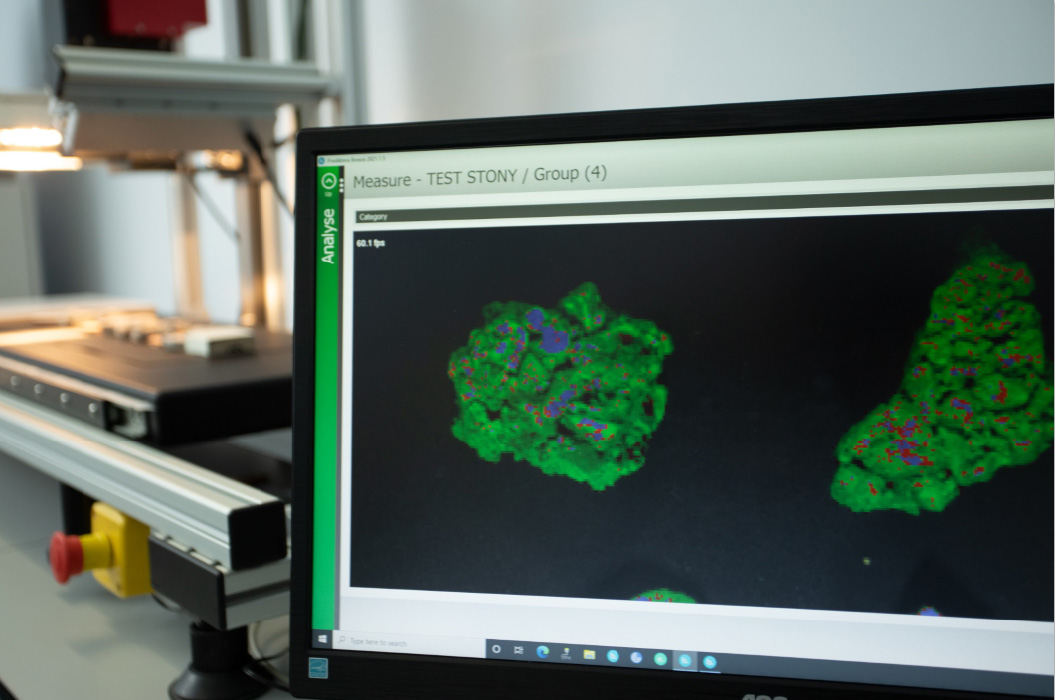

At GAIKER, we have and develop mechanical recycling technologies, such as wet or dry density separation or separation methods based on automatic identification using innovative optical sensors, as well as chemical and thermochemical recycling processes, such as solvolysis, pyrolysis or gasification.

In all these cases, we have the capacity to scale up and validate the processes developed at laboratory level, as we have an industrial area with pilot plants where we can carry out demonstrations and pilot tests of waste treatment using different technologies and in sufficiently large quantities to obtain adequate and valuable information to carry out technical and economic feasibility studies.

This capacity for process scalability also covers pre-treatments, including size reduction for the release of materials, separation of unsuitable components present in complex waste mixtures, washing, conditioning in texture and shape, etc.

We carry out the full characterisation of the waste, which is the main stage in defining both the necessary pre-treatments and the final processes selected, and we cover the characterisation of the products obtained, whether they are pyrolysis oils, carbonaceous solids if the process is thermochemical or monomers or reaction products after solvolysis processes or characterisation and market analysis of recycled plastics if the treatment has been mechanical.

The aim is to boost the effective circular economy of composite materials and of complex plastics in particular.

Leader: GAIKER

The objective is to develop artificial intelligence-based technologies to identify, sort and recover valuable metals in the recycling process of the new generation of end-of-life vehicles (ELVs).

Subsidised by the Basque Government.

The objective is to complete industrial research in order to develop chemical recycling technologies by solvolysis and selective dissolution that treat complex plastic waste, such as multilayer plastics, textiles mixed with natural and synthetic fibres or composites reinforced with glass or carbon fibres, to obtain value-added products, such as plastics, monomers or fibres.

Leader: GAIKER

Design, development and evaluation of a prototype for automatically identifying and sorting plastic waste, with brominated flame retardants based on laser-induced breakdown spectroscopy (LIBS) applied to plastics from WEEE, CDW and aviation, developing recycled plastic formulations and demonstrating their validity in high value applications.

|

This project received funding from the European Commission's Horizon 2020 research and development programme under contract number 869336. |

The project is based on designing a pre-treatment process, sorting the plastic waste in the WEEE stream, and separating high impact polystyrene (HIPS) and acrylonitrile–butadienestyrene (ABS) from WEEE for further purification and recovery of additives.

|

This project received funding from the European Commission's Horizon 2020 research and development programme under contract number 821087 |

GAIKER is involved in developing the solvolysis chemical recycling process and scaling it up, and in constructing parts made of carbon fibre from recycled material or from reusing uncured pre-impregnated offcuts by moulding them.

Developing knowledge and technology that will enable the industrial fabric to make sustainable use of plastic waste, thereby closing the life cycle of these resources. Research is ongoing on obtaining raw materials for industry using chemical (solvolysis) and thermochemical (pyrolysis and gasification) processes capable of converting plastic waste into substances that enable new plastics to be obtained.

Subsidised by the Basque Government

Development of cost-effective, sustainable chemical recycling alternatives with scalable potential, eco-design of alternative synthesis strategies to produce polymers that can be recycled and reused, evaluation of upcycling and development of predictive models.

The main aims of the project are based on developing circular economy business models for the E&E sector, ICT tools for two-way communication and secure information exchange, implementing the new circular economy business models, providing key tools to boost replicability and transferability, and maximising the impact of innovation.

Design, development and evaluation of a prototype for automatically identifying and sorting plastic waste, with brominated flame retardants based on laser-induced breakdown spectroscopy (LIBS) applied to plastics from WEEE, CDW and aviation, developing recycled plastic formulations and demonstrating their validity in high value applications.

|

This project received funding from the European Commission's Horizon 2020 research and development programme under contract number 820477 |

Recycling and Circular Economy Market Manager