Home » Functional and Sustainable Polymers » Compounding and Recovery

Compounding is the preparation of plastic formulations by mixing and/or blending polymers and additives in a molten state to achieve the desired characteristics. It is mainly a mixture of additives, such as antioxidants, UV stabilisers and other additives or reinforcing components, such as glass fibre. Compounding is generally performed by extrusion. The extruded filament material is cooled and cut into pellets of the required size.

At GAIKER, we use compounding technology to not only obtain polymers with functional or specific properties, but also to recover recycled materials, as more and more sectors are calling for the incorporation of recycled materials in raw materials for the manufacture of plastic end products.

Our main lines of work are:

Equipment to obtain thermoplastic concentrates and functional 3D printing materials.

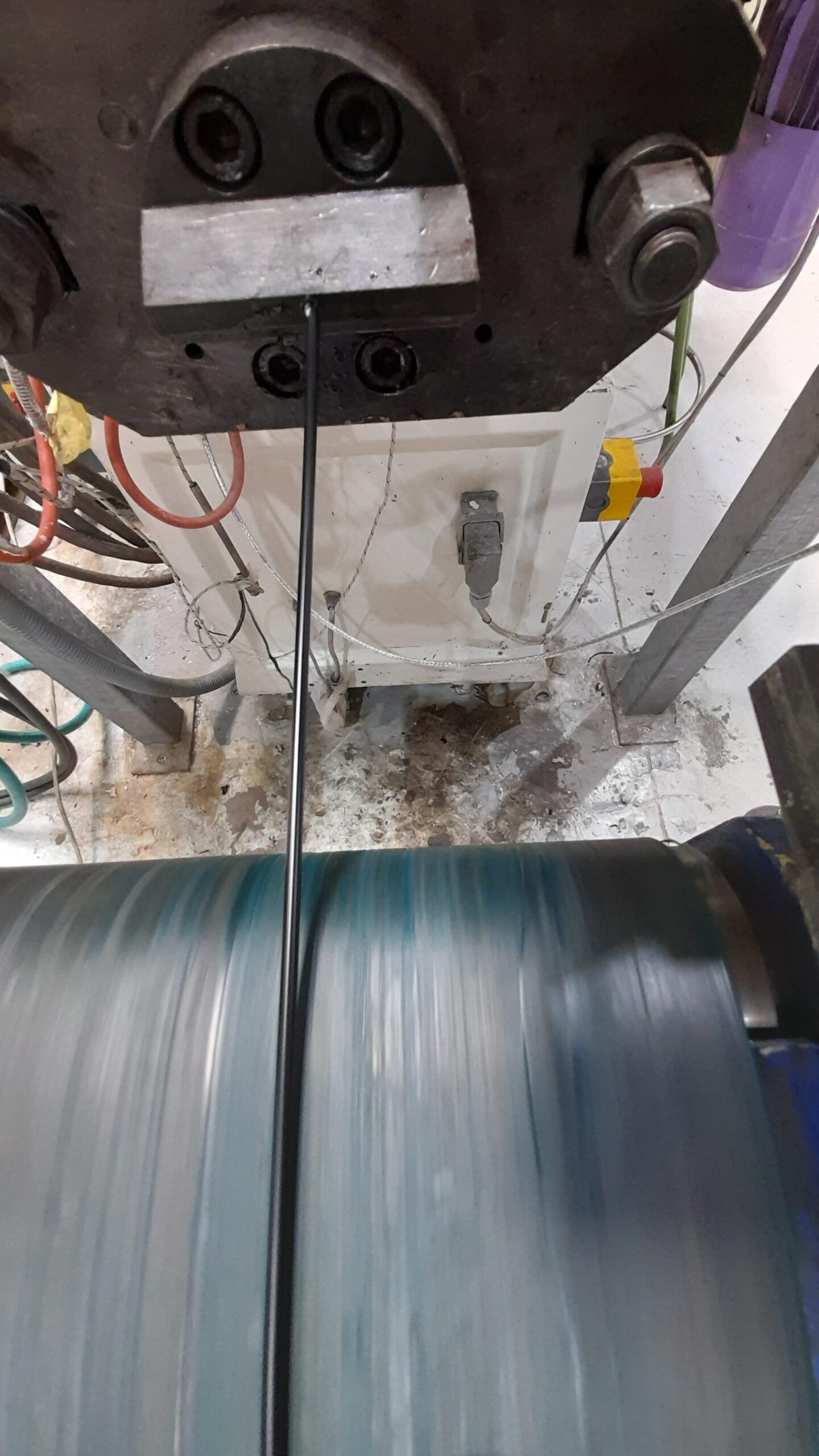

Laboratory-scale processing line for thermoplastic monofilaments.

Extruder with gravimetric dosing units and a wire shot peening and melt peening machine for low hardness materials.

Equipment to investigate the injection moulding process.

The main aim is to respond to the urgent need to set up a traceability and process control system for compounding recycled thermoplastic material to ensure a quality equivalent to the current original raw materials from fossil sources. The aim is also to define an additional suitable method and instrumentation to assist in the treatment and formulation of recovered plastic materials (extrusion compounding process), in order to ensure the highest possible quality.

The aim of the project is to develop a method to analyse and add sensors to the process and analyse data to see how the thermoplastic injection process is affected by the presence of recycled material. The aim is also to analyse the main process variables and the properties of the input material depending on the presence of recycled material and its impact on the quality of the injected part.

GAIKER is developing new polypropylene (PP) compounds from recycled polypropylene sources for use in the production process of the automotive component manufacturing company. This development includes both characterising the products currently in use and developing duplicates based on analysing the base raw material, as well as the additives, reinforcements and fillers to be added, where necessary, in order to improve the current product.

The aim of BLUENET is to reduce marine litter from aquaculture-fishing enterprises in the SE Bay of Biscay by 20-40% by 2020. GAIKER's activity is focused on recycling nets and ropes used in these industries to develop materials for manufacturing new fishing and aquaculture tools.

Sustainable Composites & Functional Polymers Market Manager